Our Cutting-edge Technologies

Achieve exceptional precision, and cost-effectiveness, with our laser-based manufacturing technologies

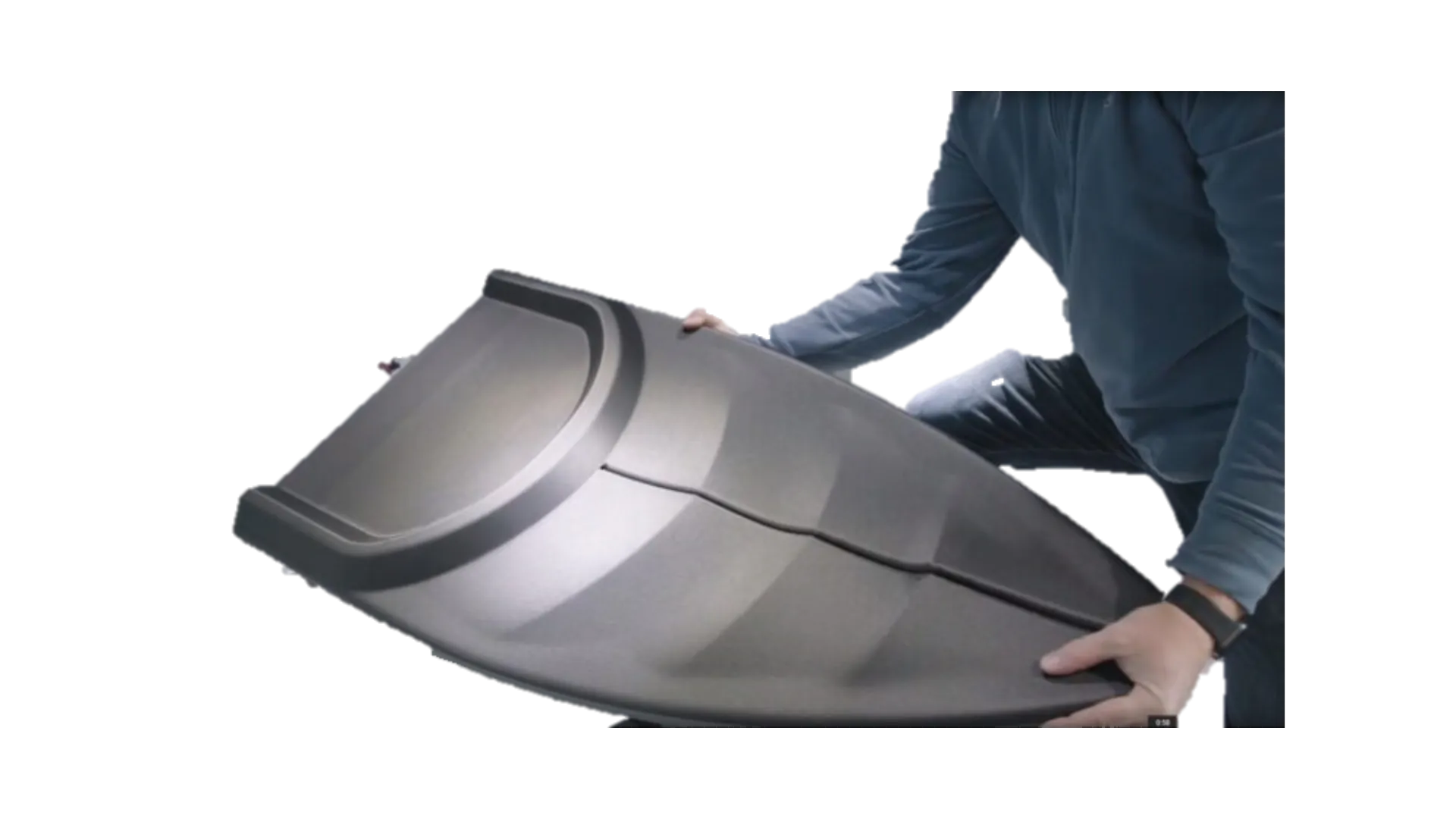

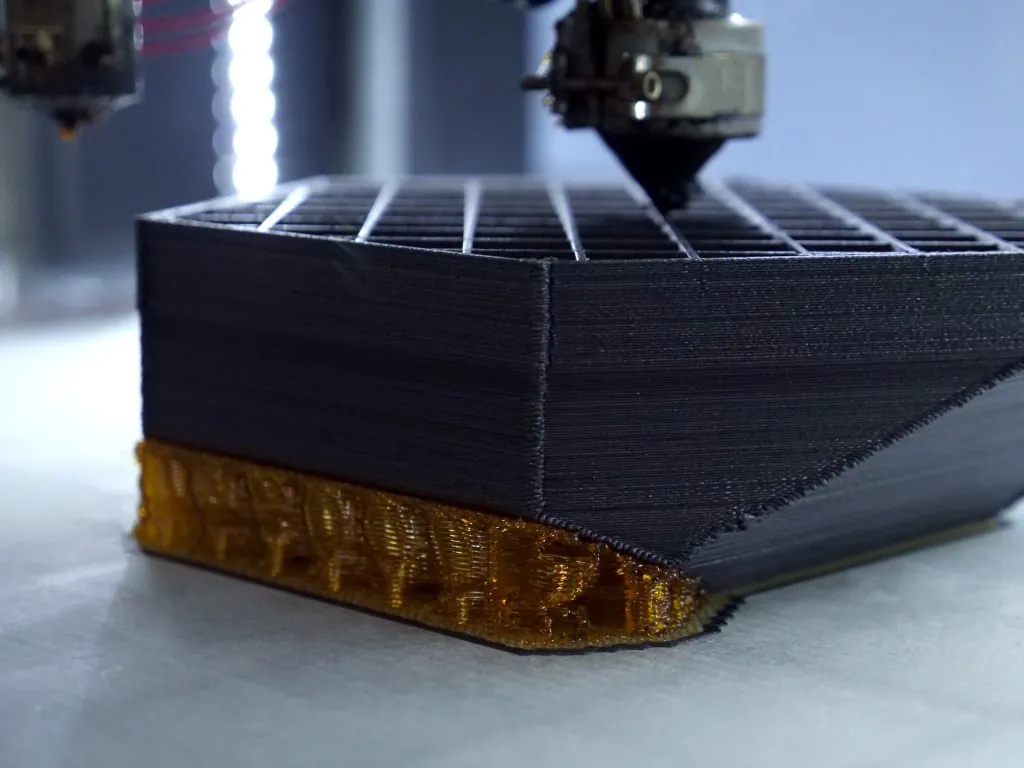

Fused Deposition Modeling (FDM)

Industrial FDM printing uses high-performance thermoplastics to produce strong, precise, and durable parts for demanding industries like aerospace and automotive. It offers superior repeatability, material versatility, and scalability for functional prototypes and end-use components.

- High Strength & Durability

- Consistent & Scalable

- Cost-Effective

- Large & Complex Prints

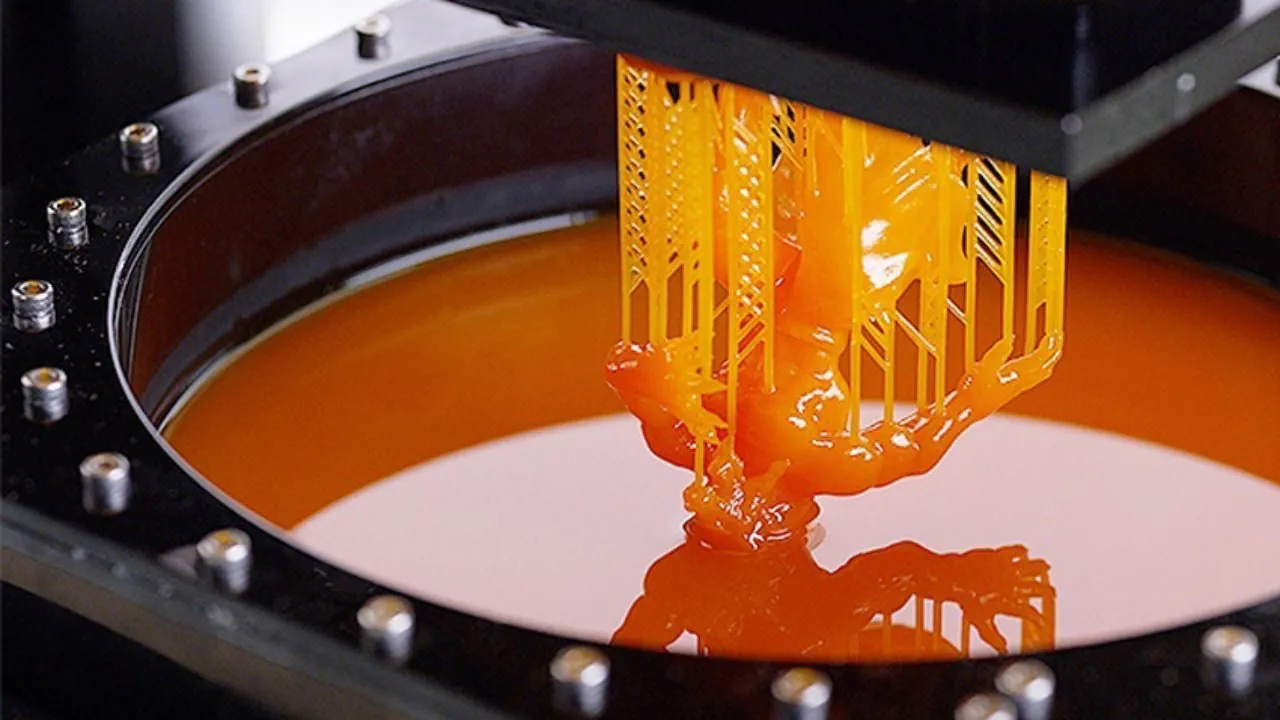

Digital Light Processing (DLP)

Digital Light Processing (DLP) printing uses a digital light projector to cure liquid resin layer by layer, enabling high-speed, high-precision manufacturing. It's ideal for applications requiring fine details, smooth surfaces, and strong mechanical properties, such as dental, jewellery, and engineering industries.

- High Precision & Detail

- Fast Print Speeds

- Strong & Functional Parts

- Smooth Surface Finish